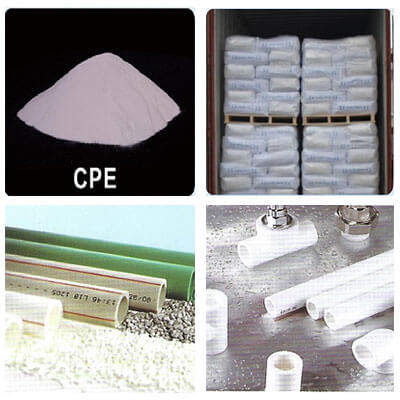

Chlorinated Polyethylene CPE Resin Manufacture: CPE resin is a polymer product made from high-density polythene material through chlorination response. According to its application, VIA Chemical CPE resin can be categorized as CPE for plastic impact modification as well as CENTIMETERS for rubber.

CPVC Resin Product Types: We offer four different CPE products that can be used in plastics, cable televisions, and also cable fields. In addition, we could tailor and generate CPE and CM inning accordance with your details requirements. Chlorinated Polyethylene CPE Material Qualities as well as Applications:

- Good impact resistance modifier with adaptability

- Great chemical resistance

- Excellent fire resistance

- Excellent temperature and also weather resistance

- Excellent processing performance

- Good loading capability

- Excellent compatibility with polyvinyl chloride (PVC), polyethylene (PE), and Acrylonitrile butadiene styrene (ABS).

CPE Resin Packaging as well as specification: CPE product embraces polyethylene bags for inner use and also polypropylene bags for exterior usage with a web weight of 25 ± 0.2 kg per bag.

CPE Resin Storage as well as transport: CPE material need to be saved in a completely dry and also ventilated storage facility with a stack height not going beyond 10 bags. Solarization as well as damp environments should be stayed clear of as well as strict precautions need to be taken again stress and anxiety. CPE is ruled out a hazardous freight.

CPE is an exceptional as well as cost-effective influence modifier as well as can considerably enhance the effect toughness and temperature resistance of stiff plastic pipeline as well as installations. CPE has excellent fire resistance and is compatible with ABDOMINAL. Thus, it can be made use of making ABS flame immune. CPE is also widely utilized in semi-rigid and also soft plastic items. As a non-migratory plasticizer for macro particle, it could enhance the product versatility and also aging and also temperature level resistance.