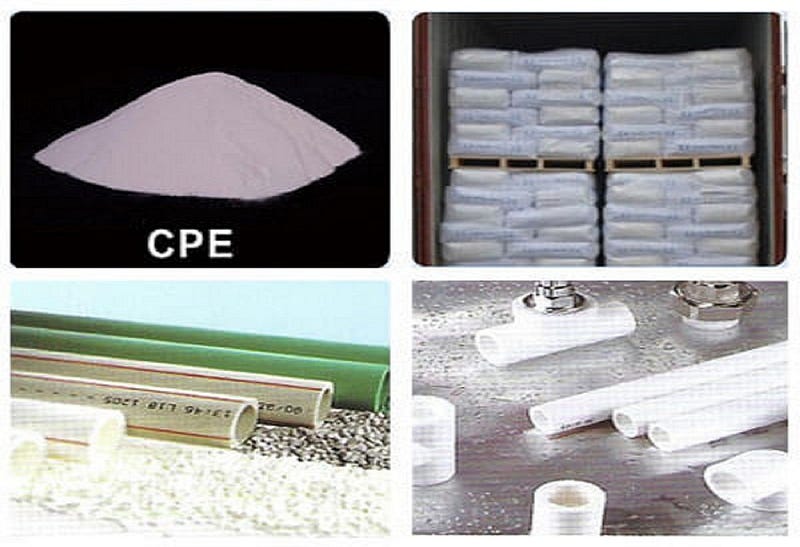

CPE resin is a polymeric material made of high-density polyethylene resin obtained from the chlorination reaction. Depending on the application, the VIA CPE chemical resin can be classified as CPE for modifying the impact of plastic and CM for rubber.

Types of CPE resin products We offer four different CPE products that can be applied in plastic, cables and cables. Furthermore, we can customize and produce CPE and CM according to your specific needs. • Good impact modifier with flexibility. • Good chemical resistance • Good flame resistance • Excellent resistance to temperature and climate • Excellent treatment performance • Good filling capacity • Good compatibility with Chlorinated Polyvinyl Chloride (PVC), polyethylene (PE) and acrylonitrile-butadiene-styrene (ABS) CPE Resin Applications

CPE is an excellent economic impact modifier and can greatly improve the impact and temperature resistance of rigid plastic pipes and fittings.

CPE has a good flame resistance and is compatible with ABS. Therefore, it can be used to make the flame resistant ABS.

CPE is also widely used in semi-rigid and flexible plastic products. As a non-migratory plasticizer for the macromolecule, it can improve product flexibility and resistance to aging and temperature.

The chlorinated CM polyethylene can be used to produce materials with a high degree of spiral impermeability and magnetic rubber, among others.

Chlorinated CM polyethylene can be used for the production of cables and sheaths (mine cables, submarine cables and locomotives), conveyor belts, corrosion-resistant gaskets and automotive rubber pipe (such as liquid brake and transport tubes), dams rubber and rubber plates, among others.

The chlorinated polyethylene CM has a good filling feature for the magnetic iron oxide powder; The magnetic material with CM will have a low temperature flexibility. Therefore, it is widely used as a sealing tape for refrigerators and magnetic cards, among others.

Chlorinated Polyethylene CM Features Good chemical resistance and to the oil of the machine. Good flexibility at low temperatures and flame resistance. Good thermal aging and resistance to atmospheric agents. Good flexural strength CM can be mixed with chloroprene rubber (CR) and nitrile rubber (NBR) to improve performance. It can also be used only as a special rubber. CPE resin Storage and transport.

CPE resin should be stored in a dry, ventilated warehouse with a stacking height not exceeding 10 bags. Sunburn and moist environments must be avoided and severe precautions must be taken against stress. The CPE is not considered a dangerous load.

Viachemical.com provides the best products.